Nature’s Garbage Disposal Transforms Pecan Waste

The Black Soldier Fly converts pecan waste to protein for use as livestock, poultry, and aquaculture feed.

Black soldier fly larvae break down waste at the FLIES Facility in College Station, Texas. (Photos by Catherine Clark)

Over the past three decades, researchers have demonstrated black soldier flies can consume most organic wastes. In fact, it would seem that the scientific community has been challenged to find an organic substrate this species cannot consume. Studies showed that this species’ larvae can feed on practically anything, including but not limited to fruits, vegetables, animal waste (e.g., dung), algae, and even decomposing animals. The black soldier fly is truly nature’s garbage disposal!

Because of the black soldier fly’s ability to recycle these wastes and produce insect biomass high in protein, a tremendous amount of research has also examined the uses of such material and primarily focused on this insect’s use as a feed for various livestock. Studies concluded the larvae of this species could be used as feed for swine, fish, poultry, frogs, and many other mass-produced livestock. This species has been approved as a feed for poultry and select aquaculture species in the United States. Additionally, the European Union approved the use of this insect as feed for select aquaculture species; other parts of the world utilize the black soldier fly in much broader forms of feed inclusion.

While the recycling of organic materials, like food waste, enhances our global efficiency with food production and utilization, we gain other benefits through this system. Feeding these wastes to larvae suppresses greenhouse gas and noxious odor emissions. Furthermore, black soldier fly larvae can also reduce or, in some cases, eliminate toxins, antibiotics, and even select pathogens in these waste materials. In this way, the black soldier fly truly offers many benefits to society.

Taking advantage of these many benefits, companies around the world mass produce the black soldier fly. This infant industry is currently experiencing massive growth globally. Facilities capable of digesting 100 tons of waste with the black soldier fly and producing up to 20 tons of larvae daily now exist. Large feed corporations are even investing tens of millions of dollars in the development of industrialized facilities. While that number is impressive, the amount of private capital being invested is even greater—reaching several hundreds of millions of dollars.

For the past 20 years, Dr. Jeffrey Tomberlin with the Forensic Laboratory for Investigative Entomological Sciences (FLIES Facility) has been exploring the black solider fly’s uses as a recycler of organic wastes and producer of protein for feed. Research out of this laboratory has resulted in practices that allowed for the black soldier fly industry to develop and expand globally.

However, the industry is still diversifying and expanding to include the recycling of agricultural waste products as well. The pecan industry, like any other agricultural sector, produces materials other than the primary commodity. In the case of pecans, shucks, deformed nuts, shells, and more are created throughout the year. Some of these materials have value, while others might not. This work led to an opportunity to partner with the Department of Entomology at Texas A&M University to explore this topic. So, during late 2019, Tomberlin and the FLIES Facility worked with Bill Ree, a retired pecan Extension Program Specialist, (IPM) with Texas A&M AgriLife, to determine if the black soldier fly could recycle pecan hulls, shells, and contaminated nuts. Ree provided the wastes; the team at the FLIES Facility tackled the study.

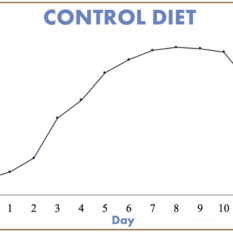

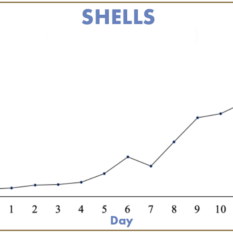

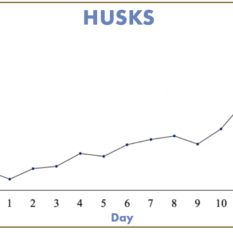

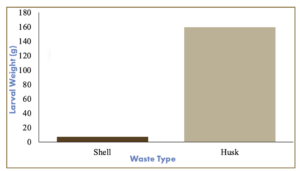

The husks and hulls were soaked in water to increase the moisture content to make the waste easier for the larvae to process. Pans containing sixteen pounds of either pecan husks, pecan hulls, or a standard fly diet—used as a control—were prepared. Approximately 10,000 black soldier fly larvae were introduced into each pan and then placed in a climate-controlled environment. Larval weights were recorded daily for 13 days and started 24 hours after the initial weights were recorded (Figures 1-3). On day 13, larvae were removed from each treatment and total weight determined (Figure 4).

The experiment worked—mostly! Black soldier fly larvae were able to recycle these materials and produce insect biomass. At the beginning of the experiment, the pan containing the hulls seemed to have high mortality rates, and the larval weights of those in the husks appeared to thrive. The hull larvae increased in weight for the duration of the experiment, but the rate at which the husk larvae increased in weight began to slow and these larvae lost weight. These data indicate that without any sort of pre-digestion preparation other than soaking the material in water, that the larvae needed twice (13 days for larvae fed shells and 11 days for larvae fed husks) as long to digest the waste than larvae on the traditional fly diet. Growth rate was also impaired on the pecan diets when compared to the control larval fly diet. However, there are solutions to optimize the larvae’s growth on these materials.

The larvae fed shells possibly increased in size due to reduced competition resulting from the initial mortality. As the husks began to decompose, the texture started to soften, and the larvae seemed to be attracted to the softer matter. When separating the larvae from the shucks at the end of day 13, the FLIES Facility found that the larvae burrowed into the husks, and there were typically more than two larvae in each piece of the husk. These burrowed larvae could be a contributing factor to the data collected, for it made the larvae more difficult to find. In the end, a total of 722.9 grams of larvae were recovered from the Gainesville (control) diet, 159.3 grams from the husk diet, and 7.0 grams from the shell diet. The small number of larvae produced when fed shells indicates that there was, after all, a high mortality rate (99 percent) versus those fed husk (50 percent mortality) or control larval diet (10 percent).

While the numbers might not be as impressive when compared to those produced when feeding larvae the control fly diet, the outcome is very encouraging. Optimizing the process for using the black soldier fly is critical. Key aspects of the process can easily be refined. For this initial study, the whole husks and shells were provided to the larvae. Future work would grind or shred the material to produce smaller particles, which the larvae can more easily ingest. Secondly the material, once digested, could be fermented, resulting in a more nutritious resource. And finally, the feed rate can be adjusted to maximize larval feeding. In the end, the maximized production of black soldier fly larvae is desired as they represent the ingredients for poultry and select fish species being developed by major feed companies, such as Cargill.

In fact, the black soldier fly is the only insect whose larvae can be sold as feed for poultry and select fish species in the United States and Canada, as previously mentioned. Packaging and selling as chicken treats could net a profit at several dollars per pound. However, the value of locally grown black soldier flies could be even greater given that most product used in the United States is imported from China.

The future is bright for the black soldier fly industry. Efforts on mass production of the black soldier fly continue to be researched globally. Global discussion in the news, at conferences, and behind closed doors by industry is optimistic about the potential for this species. But, a significant question still waiting to be resolved remains—what to feed these larvae beyond pre-consumer food waste? Can agricultural waste be used? Data presented here would suggest members of the pecan industry would have an opportunity to be a part of the insects as feed industry, too, by using the waste produced by their pecan production in a new way. Although additional work is needed to optimize the process of converting pecan waste into protein with black soldier flies, the pecan industry can look forward to another opportunity.