Five Generations of Farming, First Generation With Pecans

After 30 years in the pecan industry, Texas grower Mark Friesenhahn continues to find ways to make the most out of his 110-acre orchard.

Mark Friesenhahn brought pecans to his family's fifth-generation farm near New Braunfels, Texas. (Photo by Blair Krebs)

While the mining employees frantically fill in the crack and dig an additional pond to catch run-off, Friesenhahn bemoans the Texas Commission on Environmental Quality’s lackluster inspection of the break and takes calls from quarry representatives, the Texas Commission on Environmental Quality, the Railroad Commission of Texas, and landowner groups.

These calls make up one part of Friesenhahn’s ongoing efforts to protect his 110-acre farm near New Braunfels, Texas, from the aggregate quarries and asphalt plants around him. Like hundreds of growers across the Pecan Belt, Mark Friesenhahn confronts the increasingly common challenge of farming in the middle of urban and industrial development, while also working to maintain and build his pecan operation.

“I never thought I would know all the city council people and their mayors and county commissioners by first name,” he says, while reflecting on his 30 years as a pecan grower and his fight to protect his land. “It’s not good, but that’s what it takes. I can think of a lot more productive things to do, but if you’re going to solve [problems like this] and you’re serious about it, it takes that kind of interaction.”

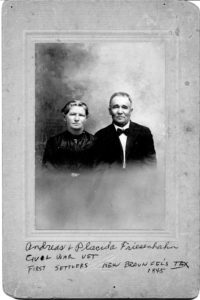

Andreas and Placida Friesenhahn settled on the land that became the family homestead in 1845. (Photo courtesy of Mark Friesenhahn)

Friesenhahn’s story begins back in the mid-1800s. He makes up part of the fifth generation of Friesenhahns who farm the land of Comal Pecan Farm. In the early 1840s, the family matriarch, Anna Friesenhahn, immigrated from Germany as part of a migration group that came through Galveston, Texas. Although Anna lost her husband along the journey, she and several of her children, including two older sons, survived the trip. Anna remarried and the family eventually settled on a plot of land along the Dry Comal Creek from 1857 to 1865.

Over the years, the Friesenhahn family raised and transitioned between a variety of livestock and crops, including cattle, sheep, cotton, grain sorghum, corn, and hay.

In the 1960s, Mark Friesenhahn’s two great uncles, who were elderly, sold their part of the family land. It is this portion that Comal Pecan Farm sits on today.

“Beginning in the mid-1980s, I had the opportunity to buy some of the land back. And I did,” he says. “Ultimately, I ended up with 110 acres here. When coupled with the 90 acres my Opa Jacob—brother to my two great uncles—owned, my two brothers, my sister, and I have around 200 acres, a half-mile off the I-35 corridor between San Antonio and New Braunfels.”

Friesenhahn says that his decision to buy back his family’s land started with the intent to simply “have a place” and to give his sons a chance to stay with their grandparents. That intention soon changed, though.

“I started with the boys growing up, helping me clear the land, keeping the two homes in shape, and doing all that in lieu of spending every Saturday in the mall with all their Houston-area city friends,” he recalls. “Then one day I was driving down the road and thought, ‘What am I going to do with that land? I gotta do something with it.’ Because my dad taught us to use the land as a farmer and make it better than you found it.”

It was at that moment that Friesenhahn decided to return to farming, but the question remained over just what to plant.

“Growing up, I rejected cattle and corn and row cropping. I hate shoveling maize and dusty row crops. Calves are only born on cold, freezing nights and have to be helped. So, I chose not to do all that,” he explains.

After asking around, Friesenhahn says he became intrigued by the differences between pecan farming and other types of agriculture. Pecans were a simple part of growing up in Central Texas. Friesenhahn recalls his family and neighbors picking up the pecan crop as it came off the trees around the local homesites; each crop was used during the holidays and as a bit of extra income. But yet, Friesenhahn never paid much attention to this tree nut until he began to get back into farming.

“You blink and ask a few questions, and then, you start planting trees,” Friesenhahn says.

These rows of ‘Pawnee’ are some of the original trees planted on Comal Pecan Farm in the early 1990s. (Photo by Catherine Clark)

So, in 1989, he began planting young pecan trees on some of the family farm’s hay and cotton fields. By 1994, he had completed planting 60 acres of ‘Wichita,’ ‘Cheyenne,’ ‘Kiowa,’ and ‘Pawnee.’ Today, he also grows ‘Mahan,’ ‘Lakota,’ and ‘Nacono.’ Looking back on that time, Friesenhahn remembers the pure joy of selling his first crop of nuts.

“I remember working in the barn across the breezeway when it still was an old barn. We took that crop by hand and sorted it out and put the nuts into racks and dried them,” he says. “I took 100 pounds of pecans—our first crop—and my two young sons, and we went to one of the farmers markets in Houston, and we sold the crop. My sons put the money in their pocket, took it home, and showed it to mom. That was our first revenue, our first farm sale.”

Friesenhahn embarked on his pecan journey while he was still working as an engineer at ExxonMobil and right as his two sons—a year apart—were approaching college.

“It was questionable at times, but my wife was a conservative German from here as well, and we pulled it off. We put both boys through school with no debt, and we kept the farm going forward and kept developing it. It wasn’t easy. I spent every spare minute that I had working on this. Only to have a growing awareness that that wasn’t enough,” he says.

Juggling his engineering career, family, and the pecan orchard, Friesenhahn found himself reaching the end of his energy rope.

“It was becoming less of enough as time went on and the orchard grew,” he adds. “Always in the back of my mind, I was going to do this right, do farming right. I couldn’t when I was working, so I split the middle and retired before age 60.”

After he retired, Friesenhahn dedicated his entire focus to Comal Pecan Farm. Over the years, he has continued to expand his pecan operation by planting more trees, building a cleaning plant, and opening an on-site retail store. Along the way, each addition was designed to solve a problem or challenge.

“I think I followed the same path that most growers do,” he says. “You start small and figure out that, ‘Man, I can’t do this by hand.’ So, then you buy the shaker and the harvester.”

With his equipment needs met, Friesenhahn soon uncovered another challenge. He realized he was spending too much time and energy driving leaves, shucks, and nuts to the closest cleaner he could find in San Saba.

So, Friesenhahn developed his own cleaning plant in the open-air barn across from his retail store and between his two blocks of ‘Wichita.’ Slowly but surely, he’s added all the necessary equipment. Most recently, he bought two upright bins to dry his pecans. All of the equipment is set on casters so that the Comal Pecan Farm team—made up of Friesenhahn and two employees, Chris Simons and Guadalupe Gomez—can roll pieces where they need them. Using his engineering background, Friesenhahn also designed and built a grading machine to better match his needs. This grading machine also reflects a learn-as-you-go project that he added to his business.

As he continued to develop the cleaning plant and general orchard management, Friesenhahn says that he realized, like other growers may, that for his operation, retail prices were better than wholesale.

“Wholesale prices for a while were really low, so I started selling pecans by the sack. That was as I could get to it and as the few customers would show up and buy 40- to 50-pound sacks,” he clarifies. “Then the Chinese market dissipated, so prices really went south. So, what do you do? You retail pecans.”

In 2016, Friesenhahn set up his retail store by transforming two bays in the barn and adding air-conditioner with one bay storing inshell pecans. After six weeks, he expanded and added two more bays for the inshell pecan area. Comal Pecan Farm continues to benefit from its location along the I-35 corridor, which connects several major cities in Texas and is a center for residential and industrial development, making the store’s customer base potentially unlimited.

As Friesenhahn quickly learned and as any pecan farmer can attest, meeting that demand requires the grower to produce top-quality pecans. But therein lies another challenge: how can a three-person operation manage a 110-acre farm and a retail store?

“I opened the store and realized to do it right you needed somebody in the store because the store and harvest go on in parallel, and you can’t do both,” Friesenhahn explains. “I found myself shaking trees in the morning, starting the harvest about 10 o’clock, and then at about 1 or 2 in the afternoon, I’d have to hop off the tractor every 30 minutes when customers started showing up. Then when they showed up 10 to 15 at a time, I couldn’t finish the harvest. That led me to hire a store manager, Debbie, who better understands the quality and equipment needed to run a retail shop.”

Friesenhahn adds that hiring a store manager allowed them to develop the store to its full potential. His store manager, Debbie Bading, brought the shop to life by painting the walls in a welcoming blue and coral and decorating it with signs and wreaths. At the same time, the team slowly built out its customer base and learned how best to display products—refrigerators, freezers, and shelving—and crack pecans on demand for customers.

To make the retail store more competitive and meet customer demand, Friesenhahn and Bading decided to add additional treats and pecan products to their catalog.

“We picked a number of products from our wholesaler’s kitchen… There are several wholesale kitchens catering to the farmer’s store market,” Friesenhahn says. “They’re totally happy to make the product for you and put your label on it and get it ready for [sale].”

Comal Pecan Farm works with Oliver Pecan Company in San Saba—a relationship that began in the early 1990s when Friesenhahn took his first crop out to be cleaned—to create and label the store’s treats. Before deciding on what to sell in their store, Friesenhahn says he looked to Oliver Pecan Company’s website for inspiration and then researched sales. Comal Pecan Farm’s store currently sells pecan butter, brittle, chocolate-covered pecans, pies, pralines, and trail mix, alongside inshell pecans and pecan oil.

Using wholesaler kitchens, Comal Pecan Farm transforms its pecans into butter, brittles, and other treats to brand and sell at the retail store. (Photo by Catherine Clark)

“We evolved that way and came to a point where prices are still low, so now we’re selling inshell pecans, cracking them on customer demand, then we sell the shelled pecan meat. Also, we’re selling not only industry pecan oil but trying to press our own oil [through The Art of Pecan],” Friesenhahn says.

Continuing to evolve his retail business, Friesenhahn began participating in a local farmers market.

“Until about May, I have totally procrastinated on [farmers markets] and avoided involvement,” he says. “Some of my friends sell their pecan things and shelled meat at the Pearl Farmers Market in San Antonio; it’s fairly upscale. There’s a farmers market in New Braunfels every Saturday and most of the towns around here have them. I wasn’t about to do that, but as it turns out, the coronavirus shut all that down.”

The shutdown, caused by the pandemic, presented Friesenhahn with an opportunity to get involved in a smaller local farmers market set up by a nearby goat farmer. At the end of May, Friesenhahn says he gave in and joined his neighbor out in front of his goat farm. Every Saturday he carries up all the pecan treats, pecan oil, and small bags of recently-cracked pecans out to his table and canopy at the farmers market to make some sales.

“Surprisingly those treats and specialty components in small quantities sell really well at a farmers market,” Friesenhahn says. “I kind of concluded that the customer focus is on the treats and the small quantities, whereas the store walk-ins are focused on pecans—buying 10, 20, 30 pounds.”

Through this close farmers market, Friesenhahn has developed repeat customers, ones who call him to check if he will be there on Saturday and make orders beforehand. By the end of June, he says he has almost sold out his stock of pecan oil. Friesenhahn further concluded that farmers markets offer another avenue to leverage a pecan grower’s ability to sell their crop and treats.

“If I had to do that all over again [set up a retail store]…You could probably ease your way into the cost of the store a little bit slower if you did farmers markets first to get a feel for the consumers,” he explains.

This observation comes after Friesenhahn experienced the expense and challenge of diving straight into the retail game.

“Instead of paying somebody to put a store up, put the AC in, paint it all in the pretty colors and get the decorations in, maybe try a farmers market to get a feel for it,” Friesenhahn recommends. “Here, it wasn’t too bad of a risk because we’re in a serious high-growth area with a lot of new subdivisions, and the word spreads quickly…The farmers market might be a good start for a small grower.”

As a small grower himself, Friesenhahn knows all too well the struggles that pecan growers with a couple of hundred acres face. He didn’t reach this point in his pecan operation—a cleaning plant, a retail store, and on-demand shelling for customers—without facing challenges, disappointments, and life lessons.

One of his most painful disappointments came early in his pecan growing career.

“If you don’t deal with the pecan nut casebearer, he will devastate your crop. And that, in fact, happened to me in 1996. [The casebearer] completely destroyed the crop. They ate all the clusters. That’s heartbreaking and demoralizing. You want to fire yourself and quit this,” he says.

But each day brings a new lesson or challenge like this one, and Friesenhahn developed his own philosophy to get through the hard times.

“I always took a deep breath and rehired myself in the morning, and I’m glad I did,” he adds.

Nutlets mature on this six-year-old ‘Cheyenne’ at Comal Pecan Farm in early June 2020. (Photo by Catherine Clark)

Friesenhahn continues to move forward and learn as he goes, just as other growers do. Now, over 30 years in his pecan journey, he has some advice and recommendations for new pecan growers.

He suggests that growers do two things before setting up shop as a new pecan orchard. First, become aware of the resources that they need for pecans and where those resources are coming from, and second, become knowledgeable on the residential and industrial growth that’s occurring around the farm.

This second suggestion comes from Friesenhahn’s own experience with the industrial development around his property.

“I thought I was going to leave Houston and Dallas traffic behind, the hustle and bustle of the subdivisions, and look out my window and say, ‘I’m deep in the heart of Texas, right where I planned to be,’” Friesenhahn remembers. “Well, I’m deep in the heart of Texas, but unfortunately, the depth of Texas is growing as fast as anywhere in the nation.”

The surrounding cities around Comal Pecan Farms are booming with subdivisions, office complexes, strip malls, and highways popping up seemingly overnight. And all of these building projects need materials: gravel, concrete, aggregate, and asphalt.

“And guess what? We’re sitting right on top of some of the best limestone in the nation,” Friesenhahn says. “So, all the multibillion-dollar international aggregate companies have moved in here and are setting up shop. Not only do they have high demand, but they are also subject to very minimal state regulations. By design, Texas favors industry and tries to minimize the regulatory climate. And that’s fine and good. I worked for the largest corporation in the nation—ExxonMobil—but we’ve gotten to a point here with the growth of subdivision, the demand for schools, the demand for services, that there are stakeholder conflicts galore now between all the people involved—landowners, residents, quarries.”

Unlike most of the nation, regulations on surface mining in Texas extend to lignite/coal, uranium, and iron ore but not aggregates. With so few rules, aggregate quarries in Texas are allowed to dig until their heart’s content. Friesenhahn further explains that these companies can “moonscape and within the law, walk away from it.”

“I am surrounded by quarries and asphalt plants now with that growth, and just the other day, some of these worries were manifested with a tailings pond break,” he adds.

To protect his land and his farm’s future, Friesenhahn has had to become more involved in the legislative process. When he first entered the pecan industry, Friesenhahn never imagined he would know his city council members, mayors, and legislators on a first name basis.

“I want to be clear… I’m not suggesting that the quarry operators are violating the law or that they’re in cahoots with the regulatory agencies or legislatures. They are simply following rules that are inadequate. And they’re inadequate because the legislature has not deemed it important to balance all the needs of the stakeholders and put more comprehensive rules in place like a lot of the other states have done,” he clarifies. “It’s a tough problem. We’re looking for equity for everybody.”

In his search for equity, Friesenhahn participates in the group Texans for Responsible Aggregate Mining (TRAM), which is made up of 11 landowner groups from all around the state. He also attends local planning and zoning meetings and continues to learn more about the legislative process. Most recently, an advisor for a local representative has asked TRAM to help with the language for several bills, including one to better the Texas Commission on Environmental Quality’s inspection procedures. Although this bill won’t fix all the problems with current aggregate mining, Friesenhahn is hopeful that it marks a step forward.

For growers everywhere, he advises that they, too, familiarize themselves with the legislative process and their representatives if they want to solve problems affecting their orchard and operation.

An aerial view of Comal Pecan Farm and the family’s antique farmhouse from 2015. (Photo courtesy of Mark Friesenhahn)

As Mark Friesenhahn continues his pecan journey, he knows other unforeseen events and problems will arise. While his engineering background helped him with designing and integrating his irrigation system and his childhood on a farm instilled him with basic farming knowledge, he believes some skills can’t be learned.

“You need to take a deep look inside your inner being—call it your soul—because there’s going to be a lot of days where you’re going to be so disappointed and so tired that you’re going to try and talk yourself into quitting,” Friesenhahn says. “I’ve kind of adopted a simple mindset that I fired myself last night, slept on it, and was lucky enough to rehire myself in the morning. In other words, the disappointment of losing a whole crop because of the casebearer and you weren’t knowledgeable enough to know what to look for or you couldn’t be there because you were working for your company, that’s really demoralizing and disappointing… You’re going to have to be able to pull yourself up by your bootstraps and keep going even though it looks like you failed completely.”

Following his own advice, Friesenhahn, after 30 years filled with successes and disappointments, never fails to rehire himself.

“If I had to do it all over again… that’s kind of the test. Yeah, I’d do it. I’d do it in a minute. There’s no way you’re going to find me on a golf course or a cruise ship. And I’ve seen enough gilded castles and European churches with gold in ’em to last me.”